A brief history of the Olga simulator

Dynamic simulation is essential in deepwater and is used extensively in both offshore and onshore developments to investigate transient behavior in pipelines and wellbores.

During the summer of 1980 two researchers from the Institute of Energy Technology (IFE) in Oslo visited Knut Åm, the technical director of Statoil at the time. Åm was looking for cost effective solutions to develop deep-water projects on the Norwegian Continental Shelf (NCS), without the need to build massive and expensive platforms for each discovery. IFE had specialized in nuclear science and research but saw declining interest due to growing public opposition to nuclear energy in the late 1970s.

The two researchers had developed a computer application called Mona, to simulate 2-phase effects of cooling water for the nuclear reactor. They were Dag Malnes and Kjell Bendiksen, and they had the idea to modify the Mona code to also simulate non-processed multiphase hydrocarbon flow for subsea developments. They presented the idea of a new transient multiphase flow simulator, and named it OLGA, from the Norwegian words for oil and gas (OLje and GAss), the first iteration of the Olga™ dynamic multiphase flow simulator we have today. Statoil was interested in the application and sponsored the first four years of research on it.

The early code showed very promising results in the first tests at the University of Tulsa laboratory. It was, however, quite clear that more laboratory and large-scale tests were required to complete and validate the code for multiphase hydrocarbon flow. At the same time the Norwegian state had started a program where foreign operators on the Norwegian continental shelf (NCS) were required to sponsor local research in Norway. In 1980 Esso invested in a multiphase flow facility at Tiller outside Trondheim. The test loop imitated full-scale installations in the North Sea, with a 52-meter-tall concrete tower (riser) topped with a separator and a 1,000-meter-long horizontal pipeline loop. Here researchers could study two-phase mixture behavior in both horizontal and vertical flow of different compositions.

The full flow loop was inaugurated in January 1983 following investments from Esso, Statoil, Mobil, Texaco, and Getty Oil, and was taken over by SINTEF in 1984. At IFE a multiphase test facility consisting of a 20-meter 4-inch pipeline with flexible inclination (0-90°) was inaugurated in 1994. These two laboratories have been key for the development of the Olga simulator and are still operational and used for validation and research studies.

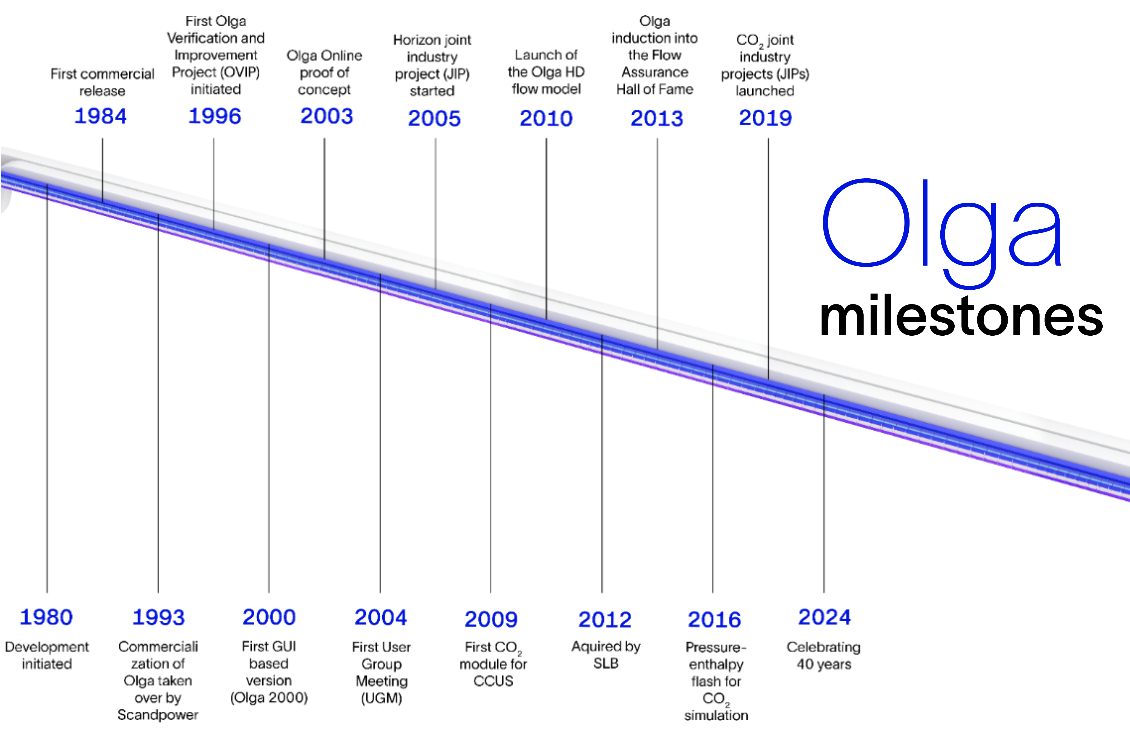

In 1984 IFE and SINTEF took over the ownership of the Olga simulator, at the same time as a new three-year joint industry project for data gathering started at the SINTEF loop with 9 industry partners: Conoco, Esso, Mobil, Norsk Hydro, Saga Petroleum, Petro Canada, Statoil, Texaco, and Getty Oil (acquired by Texaco in 1984).

More than 3000 experimental studies were performed in this period, and it also marked the start of the commercial releases of the Olga simulator, which was updated with new versions every year from the Olga84 version onwards. In the beginning the software was owned by Multiflow AS, whose ownership was split 50/50 between IFE and SINTEF. In this period IFE had responsibility for developing the code, while SINTEF contributed with empirical data from laboratory experiments.

In 1993 commercialization of the Olga simulator was given to Scandpower A/S, and the software changed name from Olga 92 to Olga-3. Scandpower was a consultancy company that had started in 1971 but was later split into three parts, with the Scandpower Petroleum Technology (SPT) divested to a venture capital fund (Energivekst AS) in 2002. SPT became SPT Group after 70% of the company was acquired by private equity fund Altor in 2006 and was finally acquired by SLB in 2012. After the SLB acquisition the Olga simulator version names again changed back to the year of release.

Equinor has named the Olga simulator the most profitable Norwegian invention, with savings of more than USD 20 billion in Norway alone. In 1999 ConocoPhillips named it one of the most important results of their research investments in Norway ever, and subsea technology (with the Olga simulator as a central part) was named the most important Norwegian invention since 1980 in a competition in Aftenposten (Norwegian newspaper) in 2012. With its wide reach in the industry the Olga simulator has also qualified and enabled complex developments and unlocked billions of dollars of savings globally during its 40 years in the market.

After 40 years the Olga simulator is still the de facto market standard for transient multiphase flow simulation and will continue to be essential for subsea development in the decades to come. As we move through the energy transition and the role of the oil and gas industry shifts, new domains make their entry, bringing new challenges and new opportunities.

A low carbon future will require new inventions, and innovations that will build on the experience of the oil and gas industry. CO2 transport and injection, and other types of liquid and gas transport, will create challenges for future engineers. As we face these challenges the Olga simulator will take its place in the future energy market; as a vibrant technology the potential of which we have only begun to see.